Understanding Quality Shed Construction

Copy Link

I want a quality shed, where do I start?

You’re in the market for a shed and excited about getting a new building! You have been browsing online, looking at different websites, pics on Facebook Marketplace and Instagram and learning your best option to move forward to get that dream shed on your property.

There is only one problem, you’re not a shed expert, and you’re not sure how to determine if the shed you plan to buy is quality and will last. How is it built and what determines if it’s good quality or bad? Well, you can relax, you’ve found the right place to learn! We are shed builders and we know sheds from the runners to the ridge cap. We have carefully written this article to empower any shed shopper with the knowledge of what makes a good quality shed

Let’s start by understanding the base of the shed, the floor system.

Most sheds are constructed on runners, usually 4×4 or 4×6 runners. 8’ and 10’ wide buildings usually have 2 runners, and 12’ wide and 14’ and 16 wide buildings usually have 4 runners. Check and make sure those runners are pressure treated runners rated for ground contact! That will ensure they have been treated properly to resist rot and decay. These runners are mainly for transportation purposes, they help the slide up onto trailers and later are set on concrete blocks in most cases.

Above the runners are 2×4 or 2×6 joists, the joists should be pressure treated as well. This will ensure the entire subfloor is resistant to decay. Make sure and ask how far the joists are spaced in the building of interest. Usually, joist spacing is 16″ on center although some sheds are built with joists 24″ on center. If the joists come standard at 16” on center you can pay to upgrade and get joists 12” on center which is a much firmer walking surface. 12″ on center joists are really great at handling heavy things like riding lawn mowers, safes, or weight lifting equipment.

Plywood or other flooring product is fastened with nails on top of the joists. This material is usually ⅝” to ¾” inches thick. Make sure and inquire as to the thickness of the flooring product that sits on top of the joists. It’s better to go thicker rather than thinner! Avoid flooring products that are ½” inches or thinner as they have a tendency to bend and warp under heavy loads. You usually can pay for an upgrade in plywood or flooring product thickness. If the standard thickness is ⅝” inch flooring inquire how much it costs to upgrade to a ¾” inch flooring product. ¾” inch flooring product is very solid when you walk on it and it handles heavy loads well. ¾” inch flooring product on top of a 12” or 16” on center joists, if constructed properly, is a rock-solid floor! Here at Sheds by Design, we use ¾” inch thick LP floor sheathing.

The Shed Siding

There are many siding products on the market and they range from basic treated siding to advanced zinc borate termite resistant siding. The siding that used on a shed is one of the biggest factors contributing to the quality and longevity. Will it crack and twist over time or will it keep its form? Is it thin and brittle or thicker and strong? Will it resist rot and decay or is it termite food in waiting? Choose carefully! Here at Sheds by Design, we use LP® Smartside® engineered siding which is resistant to water, rot, and termites! This siding comes with a 5/50 parts and labor and prorated lifetime warranty.

The Shed Paint or Sealer

Most sidings are designed to be coated in a final coat of protective paint or sealer. The kind of sealer or paint that is used is a very important element to watch for when considering shed quality. Will the sealer wear off after a couple of years? Will it need constant recoated to not void your shed warranty? Will your paint be blistering and cracking after a couple of years? Hopefully not, but that depends on the sealer or paints the shed is coated with! Here at Sheds by Design, we use Sherwin Williams® SuperPaint® which resists fading, cracking peeling, and is also mildew resistant. SuperPaint® comes with a limited lifetime warranty.

The Shed Trusses and OSB Sheathing

Above the framed walls are trusses, with steel truss plates to strengthen the joints. A quality shed will have steel truss plates holding the rafters together. The common alternative to steel truss plates is wood siding material nailed or stapled across the rafter joints. We do not recommend this method because it is simply not strong.

Nailed to the top of the trusses is an Oriented Stand Board (OSB) sheeting product. Once OSB has been attached, the roof is ready for either a shingle or metal roofing material. We use LP® OSB with Techshield® technology which helps keep the heat of the sun out of your building by blocking up to 97% of the radiant heat transfer. Installed in one million homes to date, LP® TechShield® is a proven winner in keeping buildings cooler in the heat of the sun. You can work in your shed at cooler temperatures thanks to this great feature.

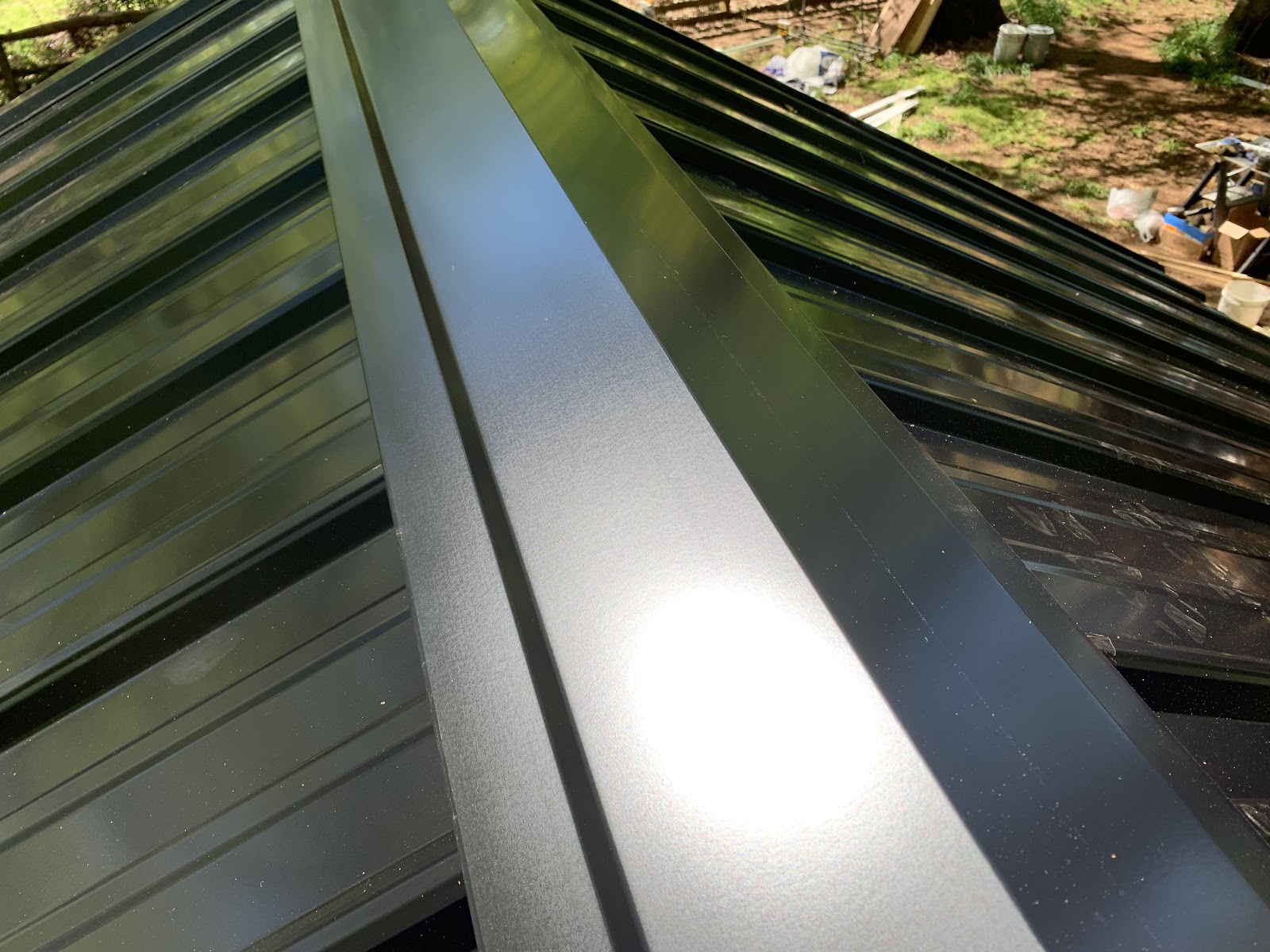

The Shed Metal Roof

Now for the metal or shingle roofing. If you have chosen a metal roof make sure that you know the brand and quality of metal roofing that is installed! Does it have a warranty what are its terms? Metal is usually fastened with screws that have rubber washers. These screws need to to tightened until the washer is firmly snug. Make sure the screws are not overnighted as this could lead to rubber washer failure and roof leaks. Here at Sheds by Design, we use a Weather XL® Sherwin Williams Coil Coatings® system with a 20-30-40 warranty. 20-year rust through – 30-year chalk and fade – 40-year adhesion. Choosing to use premium metal is one of the ways we our promise to deliver a high quality shed that has enduring aesthetic appeal. Your shed needs to be protected with a quality roof so that it stays looking good and keeps water out of your building!

The Shed Shingle Roof

If you have chosen a shingle roof make sure that you know what type and brand of shingles are being used! Are they thin 3 tab shingles or thicker architectural shingles? What warranty do they come with? When inspecting a shed roof, here are a few things to look for to ensure that you are getting a quality shingle roof system on your shed. Make sure the rows of shingles are straight and even. Make sure that your shed has drip edge installed. Without drip edge your facia trim is at increased risk of water damage. Crooked rows are a sign of sloppy installation and this is often an indicator of other sloppy install techniques that will compromise its water shedding ability. Check that there are no loose shingles, it’s possible for shingles to become dislodged during extremely high wind gusts during transportation. Look to see that there are no shingles sticking oddly up, this could be a sign that there is an improperly installed shingle edge that is not laying down and sealing properly. The sneaky thing about a leaking roof is that you usually don’t know its happening until it is exposed by a massive rot problem. Water is not a friend to lumber and needs to stay outside your shed! Here at Shed by Design, we use Landmark® CertainTeed® architectural shingles with streakfighter copper granule technology to resist algae stains. Covered by a 10-year materials and labor surestart warranty.If your shed roof leaks make sure and report it immediately to the company of purchase.

Shed Doors

Last but not least, let’s touch on the construction of shed doors. You will be using your door more than anything on your shed, it’s one of the few moving parts on a building. You want to make sure the doors on your shed are built right and will not fall apart. How thick are they? Do they have heavy duty hardware and door braces? How many layers of wood are there? Do they feel like heavy duty doors that will last? Can you lock them? Make sure you know the doors on your shed are built to last and will serve their purpose well.

Conclusion

We hope you have found this article helpful in understanding shed construction from the floor up to the roof! Make sure you are choosing to invest in a building that will last! You can’t afford to purchase a shed that is constructed cheaply and will fall apart after a few years.

If Sheds by Design can be of any service in helping you get a high quality long lasting shed that will last for years to come, message us and let us know how we can be of service to you!